| City/Town: • Dewey |

| Location Class: • Commercial • Videos |

| Built: • 1950's | Abandoned: • 1977 |

| Status: • Abandoned |

| Photojournalist: • Johnny Fletcher |

One of the major products processed at the Dad-Co mill is pellet feed used by many animals. Pellets are made of a variety of ground grains and often include molasses (a wet sweetener). The ground grains are mixed together, combined with the molasses, and then forced through a machine that creates the pellet shape.

ELEVATORS and CHUTES

A chute is a shaft or tube used to move grain in the mill. An elevator is a mechanical device (often cylindrical) for storing, lifting, and discharging grain. In this three story building, grain products are moved above the roof line, to all three floors, and to the basement for different operations. The elevators that are seen far above the roof line contain augers. The auger is shaped like a drill and lifts the grain as it spirals upward.On the roof chutes can be repositioned to divert to grain to many different parts of the mill using the openings . One chute is for millet, one for oats, etc.

Due to the possibility of explosion of the fine dust in a mill precautions have to be taken to avoid any type of sparks when moving or working with the products. Today magnets are used to as part of the safety precautions. Also, certain materials that can cause friction (such as corn cobs) are not processed at this mill.

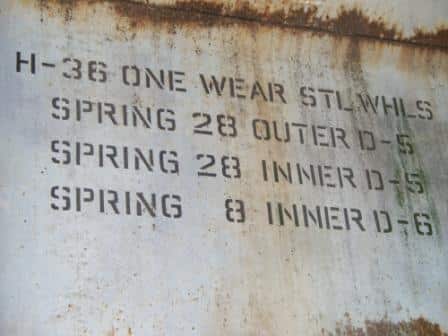

Some of the chutes and elevators in this mill are made of metal, others are made of wood. Diagonal chutes allow the product to fall without other mechanical working parts. An elevator inside the mill moves vertically is made up of a series of cup-like containers attached to a fabric belt. As the belt moves up it lifts the grain in the containers.

In the past many mill operations were done manually. A major power source of power for grist mills was water in a mill race. The Dad- Co mill never used water power. Electricity powered the machinery in the mill. Other fully automated mills today may use pneumatics (air power) or other energy sources.

DELIVERIES TO MILL

Dad- Co is built next to the railroad tracks, which in the past allowed for trains to deliver and pick up grain right at the business. Railroad cars are no longer used for delivery due to the expense. All deliveries and pickups are now done today by truck

Tractor trailers or trucks loaded with grain pull up to the trough . The auger inside turns and moves the grain up a chute to the top of the mill. The most visual part of the mill are some of the outdoor storage bins.

WHOLESALE DELIVERIES

Trucks are loaded with bulk product to be taken to local customers such as farmers. Large bins at the side of the mill can unload the product to the truck below. Blowers are usualy found on the back of the truck which assist in the delivery of the product.

Latter Years:

Johnny Scott ran the mill for a number of years during the 70’s & that it had changed hands a couple of times before his ownership & afterwords as well. He estemated the mill closed down in 1977

Gallery Below

If you wish to support our current and future work, please consider making a donation or purchasing one of our many books. Any and all donations are appreciated.

Donate to our cause Check out our books!

Wow I am falling loves to this great dad story please keep posting here!

i would agree that radon is indeed a silent killer! it could just be sitting around the corner of our houses unnoticed. this could be caused by facilities like heater or air conditioner units that are not regularly serviced or cleaned. a periodic clean-up could indeed help.

If we contrast Line and other interpersonal interaction sites than Line is a bit new application and not everybody know how to utilize this application appropriately still however the utilization of Line is not troublesome whatsoever.

I really like your post and appreciate your work. You give us many useful information about instagram.

Your site is really interesting to me and your subject matter is very relevant. I was browsing around and came across something you might find interesting. I was guilty of 3 of them with my sites. “99% of website owners are committing these 5 mistakes”. http://bit.ly/ts0ScL You will be suprised how fast they are to fix.

My dad bought cattle feed from Dad-Co feeds for years when I was a kid. My brother and I would go with him to pick up feed in our truck. Back then, the sacks were burlap, and then later years they used paper sacks. There were always lotsof cats in the storage barns. Dad-Co was a thriving feed business in the 60' and early 70's. I have fond memories of going there with my Dad. We bought all our cattle feed there, so everyone in the main office knew him well.

this place is now owned by a guy named mark, he is a truck driver, i go out there all the time, as my brother rents one of the buildings from him.

There's a new book out about the history of the American grain elevator, 1843 to 1943, called "American Colossus."

http://www.american-colossus.com

Very cool Nick! We will have to check it out! There is several grain elevators around here that we are planning on adding to the site eventually.